I have also shot a video you can watch here.

First lets start off with a few "BEFORE" pictures of the Post Drill.

After taking pictures not just so I could show a "before" look but also because taking lots of pictures really helps putting it back together, after all the parts are removed and cleaned things can look quite different.

THE DISSASEMBLY

I started by spraying all the parts with WD-40 and let it soak for a while. After a while I came back and started taking all the bolts, set screws and gears apart carefully because I didn't want to damage anything and I didn't know how weak the parts maybe... so I carefully removed all the pieces and set them on my second table trying to lay them out in some kind of order so I could keep the bolts close to the parts they belong to.

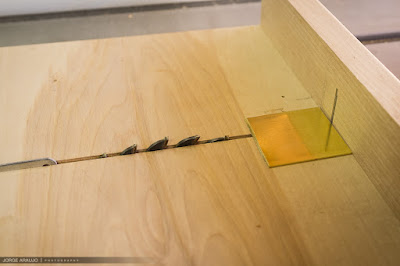

I was able to dissaemble everything except the most important part, the main shaft. I could not figure out how to separate it, so I decide to leave it and work around it. Here is a picture of the main shaft.

THE VINEGAR BATH

After I had all the parts I could remove I decided to give everything a Vinegar and Salt bath to help loosen up the Rust, Grime and old Paint. I left most of the parts in the solution for 2 days and some for more as I would take one piece out to work on it. After a while you couldn't see anything in the bath because the vinegar was so dirty.

THE CLEANING

I decided I was going to use the wire wheel on my grinder to clean all the parts. I didn't want to damage the cast iron so I decided to test it on just the handle before anything else, ofcourse it worked like a charm getting all the rust, grime and paint off and stripping it back down to just the steel. I this point I debated not to paint it because the steel looked so good, but I wanted some protection from future rust and corrosion so I was in a quandary... But I had time to decide later.

I was done cleaning everything. It took a couple of days and if you ever do a lot of wire wheel stripping I recommend a full face shield and at lease a simple nose and mouth mask... I had black dust everywhere even in my nostrils... the smell of steel we so prominent I felt dirty while I was at work because I could smell the steel on me... realizing later it was in my nose. Oh Q-Tips work really well to clean your nostrils, just be careful.

THE PAINTING

After going back and forth I decided to paint it.... It will protect it and help with future rust prevention. I thought well its about a 100 years old, I figure with this restoration hopefully it will last 100 years more. So what paint? What color? What parts get paint?

Ok first the paint I decided to go with Rustoleum Forged Hammered Spray paint in Burnished Amber color, which after I tested it looked a lot more Greyish/Silver than amber but I was ok with that because it made it look close to the raw iron.

After I painted all the Cast iron pieces I moved onto the wood back board. I cut a large piece of Cherry to size and finished it with spray Shellac.

THE FINAL PRODUCT

After a pretty simple assembly mostly because all the pieces fit together perfectly and all helpd basically with simple set screws making it super simple. A couple of things I did have to figure out was that you can't make everything too tight because it won't spin so everything has to have a bit of play to let all the spindles and gears to turn freely. After giving everything a pretty thick coat of Ballistol (my favorite oil) all the parts worked perfectly... at this point I realized I had to make a little handle for the top gear so that I could turn it backwards to raise the drill pillar after finished drilling. So at this point my restoration is finished, I am going to add a modern day Jacobs chuck so that I can use drill bits since they don't really make bits for this old school type of chuck anymore.

Ok get ready for some tool porn.