Ok so I started to work on the lid... problem is I lost the photos of the beginning parts but I will explain and its pretty easy so it should work out ok.

First remember that piece of Crotch Walnut veneer I teased in part 5? Well I took 2 sheets of that and glued it to each side of a piece of plywood, this is a very easy process of adding a whole bunch of glue to the plywood and sandwiching the veneer to it... then applying something really heavy and let it dry. Once that piece was completely dry I cut it to size and pre-finished it.

Next I cut the sides that will make the frame of the lid out of Ash, they are 2" wide, I made a 1/4"groove down the middle of the boards so I could slip the panel into and the joinery would fit nice and tight.

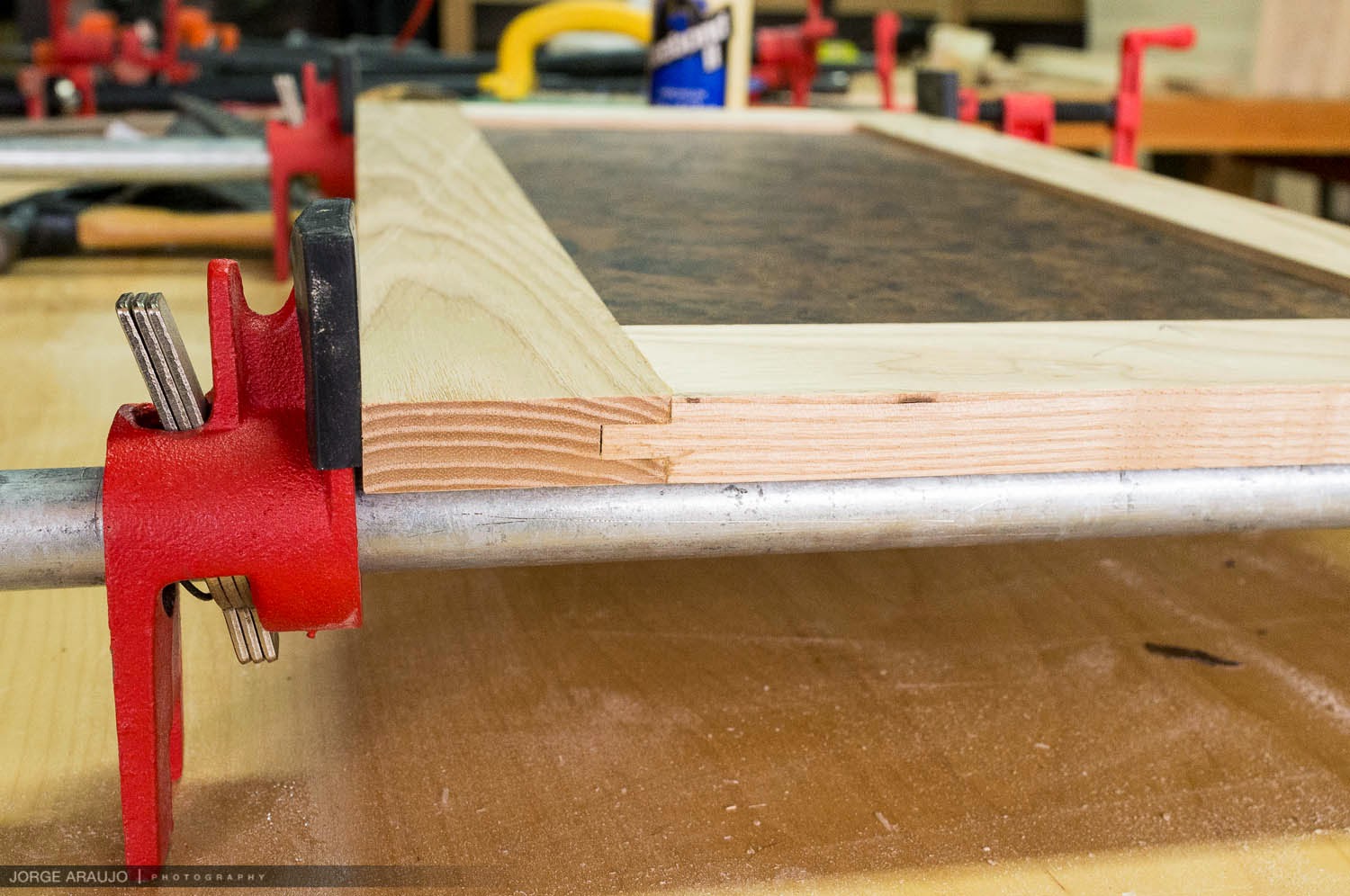

Ok in this picture you can see how it all came together, this is still a dry fit just to make sure everything fit and to adjust anything that might need it. Also you can see why I decided to pre-finish the panel, since the panel is fit in a groove about 1/2" deep if I were to finish it after I assembled it I would not be able to put finish in the edges and if there was any wood movement it has a possibility of showing where there is no finish.

In this next picture you can see how the pieces are joined together. All 4 side pieces get the groove and the short side pieces get a tenon on the ends that fit into the groove of the long pieces. Also the Walnut panel fits into the grooves on all 4 sides. The tenons I started by making the a little long and cutting them down little by little until they fit perfectly in the groove so there would be no gap. Ofcourse there is still a hairline gap, but I can live with that cuz the glue should expand the wood and fill that gap.... I hope.

Ok well now the glue up...It went pretty well, it was an easy glue up because only the sides get glue the panel "floats" in the groove" now with the plywood and veneer construction I used you don't have to leave it floating because plywood is very stable and doesn't move. The floating panel is more a practice used when you are putting a solid wood panel in the frame, so it has room to expand and contract with the humidity, but Its a good practice to get used to even with plywood and since I made the groove fit tight around the panel it doesn't rattle, it's not loose just not glued.

Now that the lid is done I will be moving onto sanding, sanding and more sanding and then applying the finish, which is going to be just a simple oil finish for the entire piece, and maybe a coat of danish oil at the end to give it a little protection.

Stay tuned cuz next post will (should) have the finish applied and the hardware installed...

Sunday, March 22, 2015

Saturday, March 7, 2015

Tool Chest Build 06 - Dovetail Drawers

Well it's been a while since my last post... life got in the way a bit... actually I spent the last couple of weekends getting my car fixed and had no time to be in the shop. But now my car is all fixed (thanks Mom!) and I have gotten back into my shop. Ok so last time I said I would probably work on the top next but I decided to tackle the drawers first instead because I might change the top design a bit.

First I milled up the walnut drawer fronts using my planer to get the stock flat and then the table saw to cut them to rough lengths... and when I say rough lengths I usually mill them about 1/16 larger then they need to be so I can finesse with my hand tools.

Then I used my plane and shooting board to get them square and to final size, final size being a tight fit into the drawer slot, I make sure they are super tight so that once the whole drawer is finished I can plane them down and give it some breathing room, usually about 1/64" side to side and 1/32" top to bottom to allow some expansion and not get locked in during the humid months.

After the drawer fronts are fit I moved onto the blind dovetail sides. First I cut the tails on the side boards and then using those I mark the sides of the front with a knife you can see the fine lines on the picture, using a saw I rough cut and I use chisels to finish it. First I chop the bottom a bit then chop down about 1/16" at a time.

Here is a picture of the final mortise all cleaned and at this point I am about to fit the side to it so I was hoping it fit.

Oh good it fit! There is a small little gap on the right side but hopefully it will swell a little with the glue and fill the gap. But other than that I impressed myself...

Hey the glue did swell it a little and the gap is not so noticeable. Want to mention that before I glued them up I did drill holes for the drawer pulls and counter sunk the backs so the screw is hidden. Do it before the glue up because it's harder after, (learned that one the hard way last time LOL!)

I glued up the sides, back and front and then slid the bottom panel in and we have a completed drawer, at this point I fit it into the drawer slot and it was way to tight, but I was expecting that, so I took the hand plane and shaved down all the sides, tops and bottoms fitting it every few shavings.

Now for the final fitting, sliding in perfectly and fit really nice. I was so excited to see the fit of the closed drawer that I made a super rookie mistake, and It is a great tip to share... wait for it...

Ok so this next picture shows the final fit I am really excited that they fit so perfect. Ok now for the tip... see those pieces of tape, well when I first fit the bottom drawer it was stuck, since it has no pulls yet I couldn't pull it back out....ooops, I actually had to do a lot of work with a chisel, ruler, tape and finally what saved me was that I had drilled the holes for the pulls and I was able to use a coat hanger to pull the drawer back out... reminded me of trying to open a car when you locked your keys in it back in the day. Then I put tape on the bottoms so I had temporary pulls and could keep fitting and be able to pull it out...LOL!

Now I am waiting for the drawer pulls they are coming from the interweb, and will be starting the lid as soon as I decide on the design... Stay tuned.

First I milled up the walnut drawer fronts using my planer to get the stock flat and then the table saw to cut them to rough lengths... and when I say rough lengths I usually mill them about 1/16 larger then they need to be so I can finesse with my hand tools.

Then I used my plane and shooting board to get them square and to final size, final size being a tight fit into the drawer slot, I make sure they are super tight so that once the whole drawer is finished I can plane them down and give it some breathing room, usually about 1/64" side to side and 1/32" top to bottom to allow some expansion and not get locked in during the humid months.

After the drawer fronts are fit I moved onto the blind dovetail sides. First I cut the tails on the side boards and then using those I mark the sides of the front with a knife you can see the fine lines on the picture, using a saw I rough cut and I use chisels to finish it. First I chop the bottom a bit then chop down about 1/16" at a time.

Here is a picture of the final mortise all cleaned and at this point I am about to fit the side to it so I was hoping it fit.

Oh good it fit! There is a small little gap on the right side but hopefully it will swell a little with the glue and fill the gap. But other than that I impressed myself...

Hey the glue did swell it a little and the gap is not so noticeable. Want to mention that before I glued them up I did drill holes for the drawer pulls and counter sunk the backs so the screw is hidden. Do it before the glue up because it's harder after, (learned that one the hard way last time LOL!)

I glued up the sides, back and front and then slid the bottom panel in and we have a completed drawer, at this point I fit it into the drawer slot and it was way to tight, but I was expecting that, so I took the hand plane and shaved down all the sides, tops and bottoms fitting it every few shavings.

Now for the final fitting, sliding in perfectly and fit really nice. I was so excited to see the fit of the closed drawer that I made a super rookie mistake, and It is a great tip to share... wait for it...

Ok so this next picture shows the final fit I am really excited that they fit so perfect. Ok now for the tip... see those pieces of tape, well when I first fit the bottom drawer it was stuck, since it has no pulls yet I couldn't pull it back out....ooops, I actually had to do a lot of work with a chisel, ruler, tape and finally what saved me was that I had drilled the holes for the pulls and I was able to use a coat hanger to pull the drawer back out... reminded me of trying to open a car when you locked your keys in it back in the day. Then I put tape on the bottoms so I had temporary pulls and could keep fitting and be able to pull it out...LOL!

Now I am waiting for the drawer pulls they are coming from the interweb, and will be starting the lid as soon as I decide on the design... Stay tuned.

Subscribe to:

Comments (Atom)