Ok so I started to work on the lid... problem is I lost the photos of the beginning parts but I will explain and its pretty easy so it should work out ok.

First remember that piece of Crotch Walnut veneer I teased in part 5? Well I took 2 sheets of that and glued it to each side of a piece of plywood, this is a very easy process of adding a whole bunch of glue to the plywood and sandwiching the veneer to it... then applying something really heavy and let it dry. Once that piece was completely dry I cut it to size and pre-finished it.

Next I cut the sides that will make the frame of the lid out of Ash, they are 2" wide, I made a 1/4"groove down the middle of the boards so I could slip the panel into and the joinery would fit nice and tight.

Ok in this picture you can see how it all came together, this is still a dry fit just to make sure everything fit and to adjust anything that might need it. Also you can see why I decided to pre-finish the panel, since the panel is fit in a groove about 1/2" deep if I were to finish it after I assembled it I would not be able to put finish in the edges and if there was any wood movement it has a possibility of showing where there is no finish.

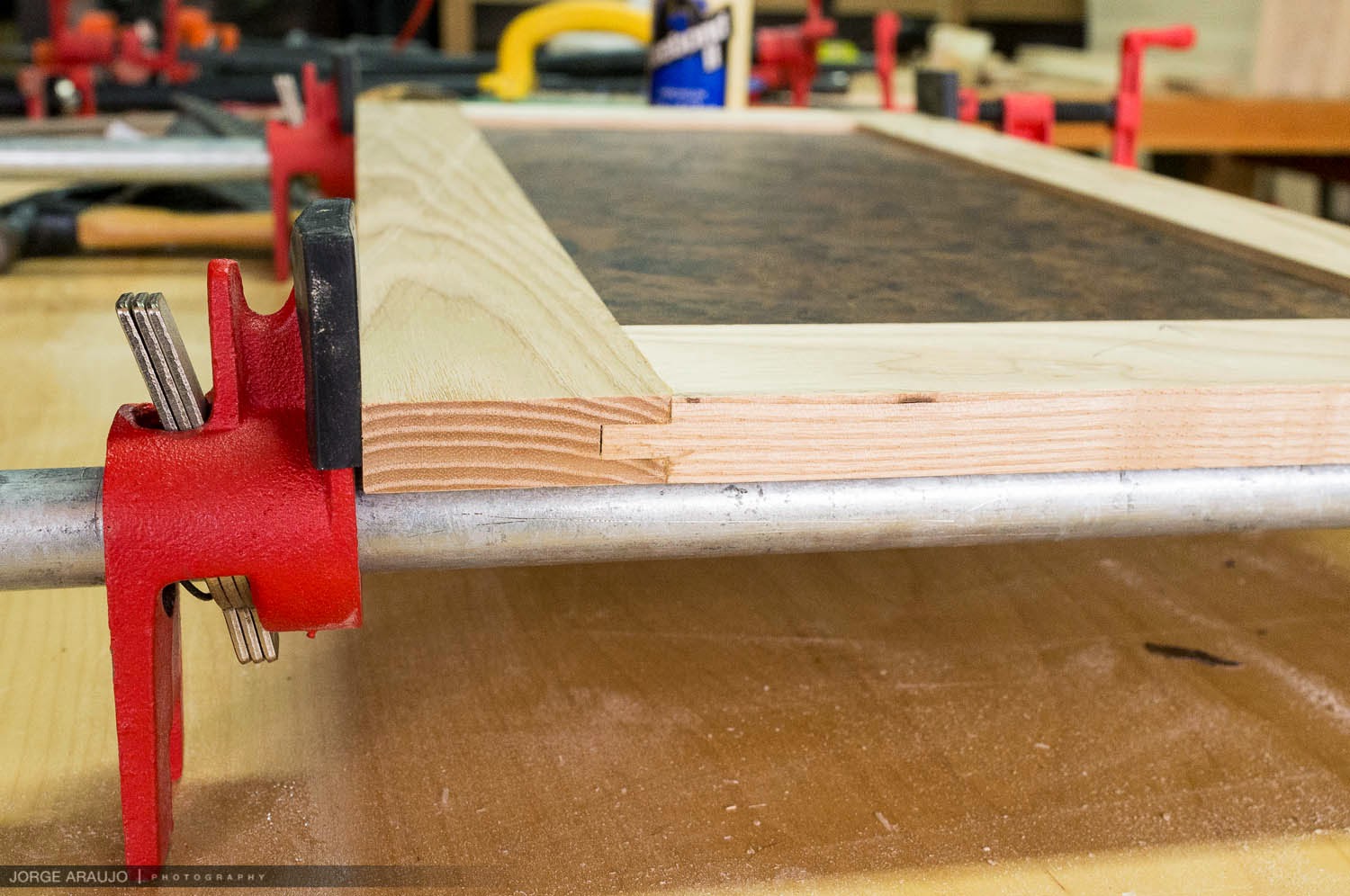

In this next picture you can see how the pieces are joined together. All 4 side pieces get the groove and the short side pieces get a tenon on the ends that fit into the groove of the long pieces. Also the Walnut panel fits into the grooves on all 4 sides. The tenons I started by making the a little long and cutting them down little by little until they fit perfectly in the groove so there would be no gap. Ofcourse there is still a hairline gap, but I can live with that cuz the glue should expand the wood and fill that gap.... I hope.

Ok well now the glue up...It went pretty well, it was an easy glue up because only the sides get glue the panel "floats" in the groove" now with the plywood and veneer construction I used you don't have to leave it floating because plywood is very stable and doesn't move. The floating panel is more a practice used when you are putting a solid wood panel in the frame, so it has room to expand and contract with the humidity, but Its a good practice to get used to even with plywood and since I made the groove fit tight around the panel it doesn't rattle, it's not loose just not glued.

Now that the lid is done I will be moving onto sanding, sanding and more sanding and then applying the finish, which is going to be just a simple oil finish for the entire piece, and maybe a coat of danish oil at the end to give it a little protection.

Stay tuned cuz next post will (should) have the finish applied and the hardware installed...

No comments:

Post a Comment